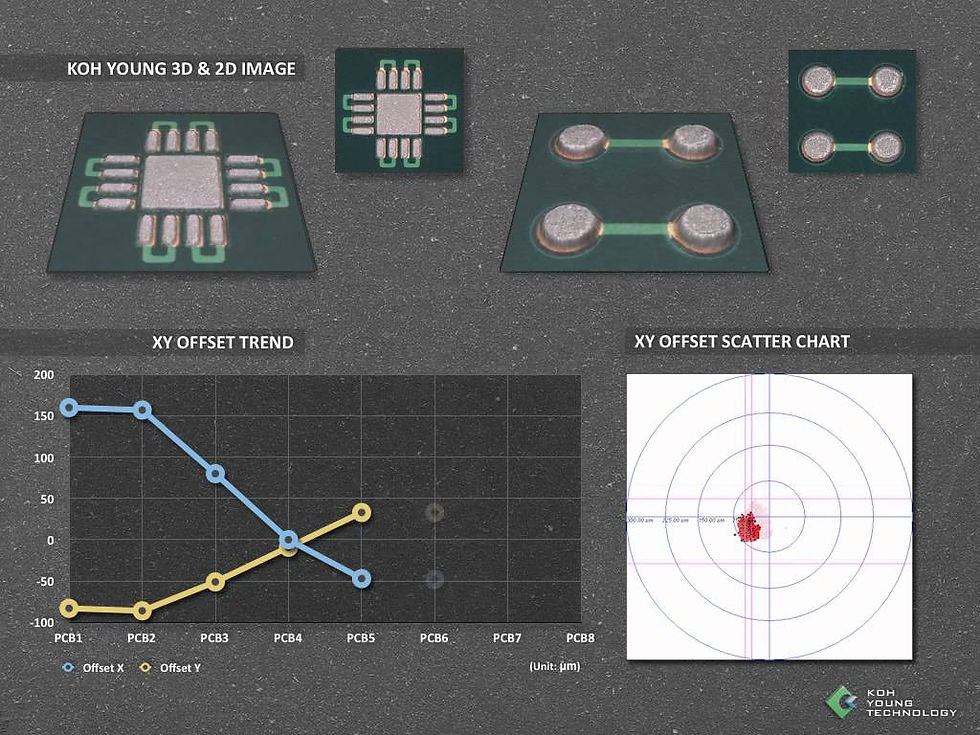

Circuitwise uses a 3D SMT Solder Print Inspection System which allows us to view in 3 dimensions the Solder Paste Deposition. This is initially used as part of a wider First Article Inspection procedure established.

At Circuitwise we perform First Article Inspections every time we set up for a production batch or run. The procedure is that we first set up the screen printer and print the first PCB. This PCB is analysed usiing the 3D Inspection System which is used to adjust solder volumes in critical areas of the PCB. This is especially important when printing micro BGA's and LGA type devices. Once the perfect volumes of paste is established this data is used to program the 2D AOI built in to our main line screen printers. Once programmed these will monitor 100% the balance of the production run or batch.

Almost 80% of all defects in SMT can be attributed to the screen printing process. Using this system allows us to cut out most defects connected to this process. As well our screen printers 2D AOI allows the system to proactively monitor paste coverage ongoing for the batch. Rather than the traditional process in screen printing to print 5 times then clean the stencil in order to stop drying paste to reduce stencil aperatures we actively monitor 100% of all prints and clean stencils once aperatures reduce. This can happen after 5-10 prints or possibly after 1 print.

These days with complex PCB designs one cannot rely on traditional processes to monitor output, they must be monitored in real time in order to achieve maximum results regarding first off pass rates. Especially with PCB's that contain micro BGA's and LGA devices which are dificult at best to inspect after reflow. The Manufacturer must ensure the process is on the mark at all times.

Please contact us now for a free Demo.

Greg Ross

Circuitwise Electronics