Did you know we manufacture right here in Sydney? Read more

Component traceability for medical devices

Traceability of the components is a critical part of the quality assurance processes required to gain regulatory approvals for medical devices.

The ISO 13485 Quality Systems Standard for Medical Devices requires that the product owner shall “plan and develop the processes needed for product realization” including “traceability activities specific to the product together with the criteria for product acceptance”.

The company needs to document procedures that define the extent of traceability required for applicable regulatory requirements and what records need to be maintained. The standard specifically requires an organisation to “maintain records for each medical device or batch of medical devices that provides traceability for each”.

Most companies developing medical devices with electronic components will outsource Printed Circuit Board Assembly (PCBA) to a contract electronics manufacturer like Circuitwise that has ISO 13485 certification.

Traceability means the manufacturer needs to keep track of where every single component has come from and where it goes. This information is stored as part of the Device History Record that the product owner must maintain.

Most medical devices are Class IIa or Class IIb and implementing traceability at the batch level is usually sufficient. However, for applications where correct operation of the device is critical to sustaining or supporting a patient’s life (Class III), product manufacturers will ask for traceability at the device level. See the blog post on our contribution to development of emergency ventilators as an example.

Tied in with traceability is the concept of identification. Each component and each assembled product must have a unique identifier so that only products that “have passed the required inspections or testing is released for dispatch, use or installation”.

At Circuitwise, every PCBA has a serial number that facilitates our ability to keep records which components are used on any particular board. This ability is enabled by the Cluso inventory management system developed in-house at Circuitwise and now exported globally.

The main steps in the PCB assembly process where traceability is critical are as follows:

-

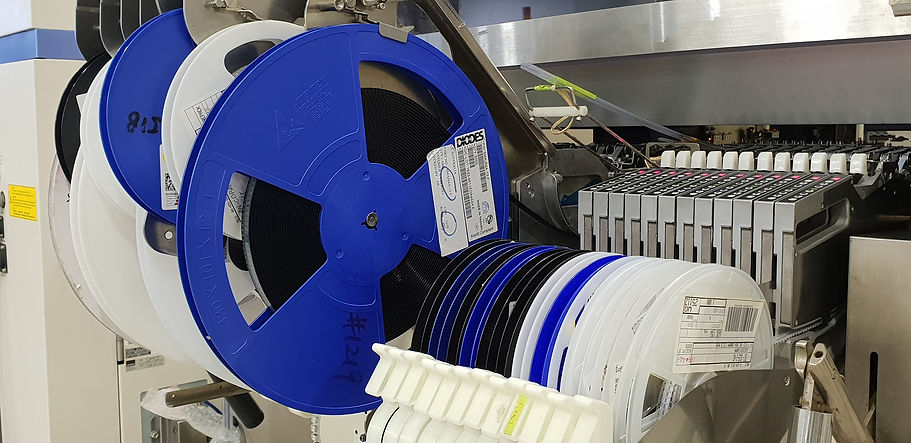

Incoming goods inspection and acceptance: Every part (including reels of parts or other packaging formats) entering the Circuitwise factory is photographed and a serial number attached. We check what we received is what we ordered and capture supplier information.

-

Storage of components: Parts are stored in the Cluso smart storage system that facilitates easy and accurate retrieval of components from thousands of reels on the shelves. Each component is logged as it goes onto a shelf and the system ensure first in is first out.

-

Pick and place production: As components are retrieved from the smart storage and allocated to the pick and place machines, they are again logged. Serial numbers are assigned to PCBs and captured in the Cluso system. A range of other information in captured during preparation for a production run including ensure the correct stencil is used, the lot number of the solder paste, its shelf life, temperature of the paste, last maintenance date of the paste printer, what version of Pick and Place program placement is used etc.

-

Reflow: As the assembled PCB passes through the reflow oven, we record the temperature profiles used in the oven.

-

First article inspection: The first PCBA is inspected to ensure it is 100% correct. This is used as a golden board for Automated Optical Inspection. A report of this first inspection is recorded.

-

Automated Optical Inspection: Although not strictly necessary for medical devices, we maintain records of the AOI inspection of each PCBA.

-

Through hold parts assembly: If the PCBA requires additional placement of through-hole components, then a similar traceability checks and records are undertaken as for the pick and place process.

-

Electrical testing: As firmware is uploaded, its version number is recorded. After upload, very board undergoes electrical and functional testing to ensure it is working correctly. Records of the tests are entered into the Cluso system.

-

Conformal coating: Were conformal coating or other processes are required to finish off the boards, records are again taken.

-

Final assembly: Where Circuitwise assembles the final product the mechanical components are put through the same traceability regime to ensure every part is traced through to the final product.

-

QC inspection: Prior to shipping the device undergoes a final quality control inspection, with procedures provided by the product owner. Records of the inspection are taken and certificates of conformity are issued.

-

Packaging: Traceability is required in every aspect of the product delivery process. So again records are taken of the packaging used and any additional items included in the box, such as instructional materials. Where necessary, photographs are taken to prove all necessary items were present as the box was sealed.

This rigorous system generates many traceability benefits. For example, if a component is sensitive to moisture, it is placed in a dry cabinet until it is ready to be used. When it is taken out of the cabinet, the reel is scanned and the time it is out of the cabinet is logged. In this way, if there is ever a problem with moisture sensitive components in the field, we can provide evidence that the component’s exposure to moisture before manufacture was fully controlled.

Another benefit is that the operator using the Cluso system is automatically logged. So we know which operator took a reel from storage and placed it in the pick and place machine. If there is an error with either the system or with the operator following procedures correctly, we can take corrective action – which is the essence of a quality system.

For more information on other aspects of quality systems required for electronic medical device manufacturing, see our Spotlight on ISO 13485 blog post. You can also view a webinar on Design for Manufacture of Medical Devices delivered by Circuitwise General Manager Serena Ross. Please also review our MedTech Manufacturing Services.

Above is an image of a board being compared to a customer design. During each run, we inspect the first board to ensure it is 100% correct – producing a golden board. Our unique first article inspection system automates the process of comparing the golden board against the design supplied by the customer.

Above is an example of a new PCB assembly rigged up with sensors and ready for profiling. We use this to optimise the temperatures in the reflow ovens. More on custom reflow profiling.

Above is our Saki PCB optical inspection machine. We use Saki and Yestech machines for autonomously inspecting each board coming off a run against the golden board. We check for shorts and opens, solder joints and other joint defects with reference to IPC 610. We ensure the correct components are in place including polarity and location.

Above is an example of an electrical testing device. More on electrical testing. We conduct in-circuit testing that checks for shorts and opens in the circuit board tracks as well as the values of basic components such as resistance, capacitance and inductance. These tests are typically conducted using a bed-of-nails tester supplied by the electronics designer.

After uploading firmware, we conduct functional testing to verify the device is working as intended, using a testing system supplied by the designer. We can also stress-test the device by conducting these tests at high and low temperatures and cycling between these extremes. The environmental chamber can also test devices in high humidity conditions.